Water pumps are essential pieces of machinery used to move water from one place to another. They can be found in a variety of applications including irrigation systems, construction sites, firefighting operations, and even in residential settings for draining flooded areas. One key component of a water pump system is the engine that powers the pump through a hose. In this article, we will delve into how a water pump engine works in conjunction with a hose to efficiently pump water.

How Does a Water Pump Engine Work with a Hose?

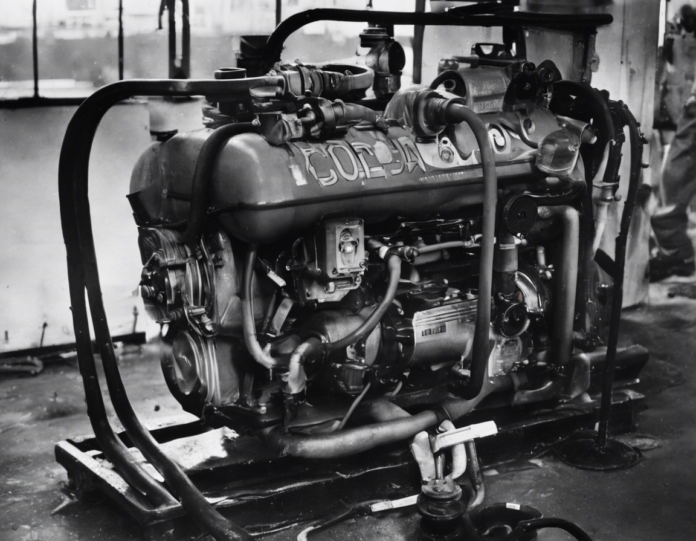

1. Engine Power: The engine serves as the powerhouse of the water pump system. It provides the necessary mechanical energy to drive the pump and move the water through the hose. Gasoline engines or diesel engines are commonly used to power water pumps, depending on the size and intended application of the pump.

2. Intake: The hose attached to the pump acts as the intake, drawing water from a water source such as a reservoir, tank, or body of water. The intake hose is submerged in the water to ensure a continuous flow to the pump.

3. Impeller Action: Within the pump housing, there is an impeller – a rotating component with curved blades. As the engine powers the impeller, it spins rapidly, creating a centrifugal force that pushes water outward. This action increases the water pressure inside the pump.

4. Discharge: The high-pressure water is then forced out of the pump through another hose, known as the discharge hose. This hose directs the water flow to the desired location, whether it be a field, a fire, or a drainage area.

5. Hose Size and Length: The diameter and length of the hoses used in the water pump system play a crucial role in its efficiency. Larger diameter hoses can accommodate higher water flow rates, while longer hoses may result in decreased water pressure due to friction loss.

6. Pump Priming: In some cases, water pumps need to be primed to remove air from the system and create a vacuum that allows for proper water suction. This is especially important for self-priming pumps that may lose prime after extended periods of non-use.

7. Maintenance: Regular maintenance of the water pump engine and hoses is essential to ensure optimal performance. This includes checking for clogs, leaks, and worn-out parts, as well as changing the engine oil, filters, and spark plugs as needed.

Benefits of Using a Water Pump Engine with a Hose

- Efficiency: Water pumps powered by engines are highly efficient in moving large volumes of water quickly.

- Versatility: They can be used in various settings and applications, from agricultural irrigation to dewatering flooded areas.

- Portability: Some water pumps are portable and can be easily transported to different locations as needed.

- Reliability: Engine-powered water pumps are known for their reliability and consistent performance, making them essential in emergency situations such as firefighting.

Common Types of Water Pump Engines

-

Gasoline Engines: Often used in smaller water pumps for residential or light commercial applications due to their ease of use and maintenance.

-

Diesel Engines: Preferred for larger water pumps requiring higher power output and increased durability for continuous operation.

-

Electric Motors: While not engines in the traditional sense, electric motors are also used to power water pumps, especially in stationary or indoor applications where exhaust emissions are a concern.

Tips for Proper Use of a Water Pump Engine and Hose System

- Check for Leaks: Regularly inspect hoses for leaks or damage that could affect water flow and pressure.

- Monitor Engine Oil: Ensure the engine oil levels are sufficient and change the oil as recommended by the manufacturer to prolong the engine's lifespan.

- Secure Connections: Tighten hose connections to prevent leaks and ensure a consistent water flow.

- Store Properly: When not in use, store the water pump and hoses in a cool, dry place away from direct sunlight to prevent deterioration.

Frequently Asked Questions (FAQs) About Water Pump Engines and Hoses

1. Can I run a water pump without a hose?

- No, a hose is essential for both the intake and discharge of water in a water pump system. Without a hose, the pump would not be able to effectively move water from one location to another.

2. How do I determine the right size of hose for my water pump?

- The hose size should match the pump's outlet size to ensure compatibility. Additionally, consider factors such as the intended flow rate and distance the water needs to travel when selecting a hose.

3. What is the difference between a suction hose and a discharge hose?

- A suction hose is used to draw water into the pump from a water source, while a discharge hose is used to expel water from the pump to the desired location.

4. Can I use multiple hoses with a single water pump?

- Yes, depending on the pump's design and capacity, you can use multiple hoses to increase water distribution or reach different areas simultaneously.

5. How do I prevent clogging in the hose and pump system?

- To prevent clogging, avoid pumping debris-laden water and install a strainer at the intake to filter out larger particles before they enter the pump.

In conclusion, water pump engines working through hoses play a crucial role in various industrial, agricultural, and residential applications. Understanding how these components interact to efficiently move water is essential for proper maintenance and operation of a water pump system. By following best practices, conducting regular inspections, and addressing any issues promptly, you can ensure the longevity and effectiveness of your water pump engine and hose setup.