Producer gas, also known as wood gas or synthesis gas, has been utilized as a fuel source for decades. It is a mixture of carbon monoxide (CO), hydrogen (H2), carbon dioxide (CO2), methane (CH4), and nitrogen (N2), along with traces of other gases and particles. The composition of producer gas can vary based on several factors, including the feedstock used, the gasification process, and the operating conditions. In this comprehensive guide, we will delve into the composition of producer gas, its properties, applications, and the processes involved in its production.

Composition of Producer Gas

The composition of producer gas can be influenced by the type of feedstock used and the gasification process. However, some general trends can be identified:

Carbon Monoxide (CO)

Carbon monoxide (CO) is a primary component of producer gas, typically constituting around 20-30% of the gas composition. It is a flammable gas that burns with a blue flame and is an important fuel gas in various industrial processes.

Hydrogen (H2)

Hydrogen (H2) is another significant component of producer gas, comprising around 15-25% of the gas composition. It is a high-energy fuel that burns cleanly, making it an attractive option for fuel cell technologies.

Carbon Dioxide (CO2)

Carbon dioxide (CO2) is usually present in producer gas in smaller quantities, around 5-15%. It is a non-flammable gas and typically considered an undesired component in fuel gases due to its low heating value.

Methane (CH4) and other Hydrocarbons

Methane (CH4) and other hydrocarbons can be present in trace amounts in producer gas, depending on the feedstock and gasification conditions. These gases contribute to the overall heating value of the gas.

Nitrogen (N2)

Nitrogen (N2) is often present in significant quantities in producer gas, typically making up 50-60% of the gas composition. While inert in combustion processes, nitrogen dilutes the gas and lowers its heating value.

Trace Gases and Impurities

Producer gas may also contain traces of tar, particulate matter, sulfur compounds, and other impurities depending on the gasification process and feedstock used. These impurities can impact the combustion efficiency and environmental emissions of producer gas.

Properties of Producer Gas

Producer gas exhibits several key properties that make it a versatile fuel source:

- High Heating Value: Producer gas has a high heating value, making it suitable for various industrial applications.

- Flammable: The flammable components of producer gas, such as CO and H2, make it a viable fuel for combustion processes.

- Variable Composition: The composition of producer gas can be tailored based on the gasification process and operating parameters.

- Low Tar Content: Proper gasification processes can minimize tar content in producer gas, reducing equipment fouling and maintenance issues.

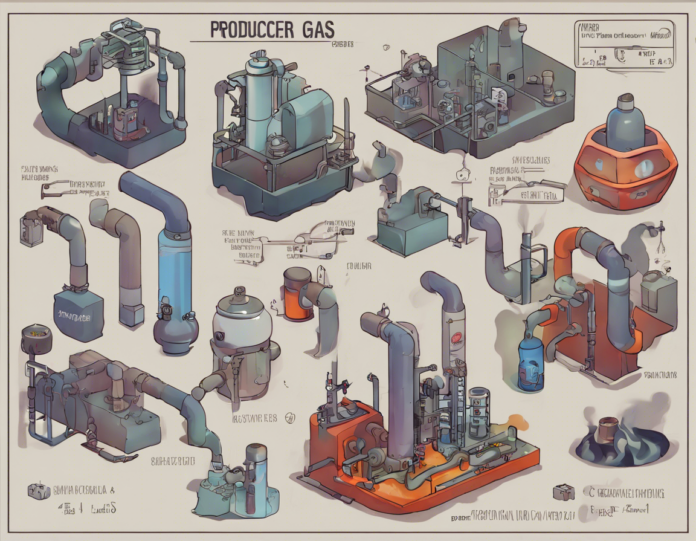

Gasification Processes

The production of producer gas typically involves gasification processes, where solid or liquid feedstocks are converted into a gaseous fuel. Common gasification methods include:

- Partial Oxidation: Involves the partial combustion of feedstock at high temperatures to produce producer gas.

- Steam Reforming: Utilizes steam to react with carbonaceous materials to produce H2 and CO-rich producer gas.

- Biomass Gasification: Specifically designed for biomass feedstocks, this process produces producer gas with sustainable and renewable characteristics.

Applications of Producer Gas

Producer gas finds diverse applications across various industries, including:

- Heat and Power Generation: Producer gas can be used in gas engines or turbines to generate heat and electricity.

- Industrial Processes: It is employed as a fuel in industrial furnaces, kilns, and boilers.

- Chemical Production: Producer gas is a feedstock for chemical synthesis processes.

- Transportation: It can be utilized as a fuel for vehicles, particularly in gasification-based transportation systems.

Frequently Asked Questions (FAQs)

1. What is the difference between producer gas and biogas?

Producer gas is derived from the gasification of carbonaceous materials, while biogas is produced through the anaerobic digestion of organic matter. Producer gas primarily contains CO, H2, and other gases, while biogas is predominantly methane.

2. Can producer gas be used for heating applications?

Yes, producer gas can be effectively used for heating applications in industrial processes, residential settings, and commercial buildings. It provides a high heating value and can replace traditional fossil fuels in heating systems.

3. How can impurities in producer gas be minimized?

Impurities in producer gas, such as tar and sulfur compounds, can be minimized through proper gasification processes, use of clean feedstocks, and appropriate gas cleaning technologies like scrubbers and filters.

4. Is producer gas a sustainable fuel option?

Yes, producer gas can be a sustainable fuel option when derived from renewable biomass feedstocks. Biomass gasification technologies offer a carbon-neutral alternative to fossil fuels, reducing greenhouse gas emissions.

5. What are the challenges associated with producer gas utilization?

Challenges related to producer gas utilization include the need for efficient gasification technologies, management of by-products like ash and char, integration with existing energy systems, and ensuring consistent gas quality and composition.

In conclusion, the composition of producer gas can vary based on several factors, with carbon monoxide and hydrogen being the key components. Producer gas offers a versatile fuel source with applications in heat and power generation, industrial processes, chemical production, and transportation. By understanding its composition, properties, and production processes, we can harness the potential of producer gas as a sustainable energy solution.